-

Radiator Making Machine

-

Radiator Core Builder Machine

-

Radiator Fin Forming Machine

-

Ultrasonic Cleaning Machine

-

Industrial Vacuum Packaging Machine

-

Aluminum Brazing Furnace

-

Radiator Leak Tester

-

Radiator Tube

-

Plastic Radiator Tank

-

Aluminum Foil Sheets

-

Weldable Aluminum Sheet

-

Radiator Plate

-

Metal Working Lubricant

-

Aluminum Brazing Flux

-

Radiator Components

8-Cylinder 200-Program Radiator Making Machine

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Core Size | 1000×900×56mm | Indenter | 20/30/40mm (Selectable) |

|---|---|---|---|

| Dimensions | 1800×1600×1800mm | Weight | 1100kg |

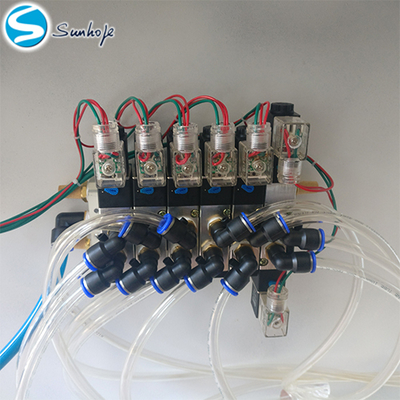

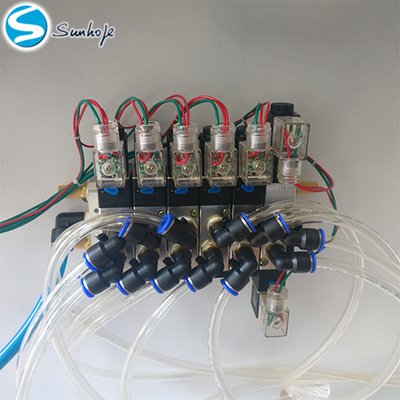

This pneumatic crimping machine, equipped with a servo motor and PLC controller, is designed for high-volume production of specific radiator models. It offers fast operation speed and user-friendly controls. The PLC allows programming and storage of up to 200 distinct working programs for different plastic radiator tanks.

The machine is used to crimp the header plate teeth, securely locking the plastic tank onto the core. This process creates a sealed space between the crimped plastic tank, the sealing gasket, and the header plate. It features dedicated long-side head crimping and end crimping mechanisms, enabling both long and short side headers to be crimped in a single machine cycle. It is versatile and suitable for crimping various radiator products.

- Flexibility: Selectable indenter widths (e.g., 20mm, 30mm, 40mm) for different tab pressing plate requirements.

- Ease of Maintenance: Simple daily upkeep procedures.

- High Efficiency: Fast cycle times and streamlined operation significantly save production time.

- Programmability: Stores programs for 200 different models, enabling quick changeovers.

- Precision & Control: Servo-pneumatic drive ensures accuracy and adjustable speed.

- Dedicated personnel inspect every production stage to ensure quality.

- Professional engineers conduct rigorous quality checks.

- All products comply with international standards, holding CE, FCC, ROHS certifications.

| Feature | Specification |

|---|---|

| Cylinders | 8-12 |

| Programs | 200 models (PLC) |

| Output | 60-80 pcs/h |

| Power | 220V/50Hz, 2.5kW |

| Drive | Servo-Pneumatic (0.8MPa) |

| Core Size | 1000*900*56mm |

| Indenter | 20/30/40mm (Selectable) |

| Workstations | 4 |

| Speed | Adjustable |

| Dimensions | 1800*1600*1800mm |

| Weight | 1100kg |

For over 15 years, SUNHOPE has been a leading manufacturer and developer specializing in automotive radiator and condenser components, exporting globally. Our expertise encompasses the entire radiator production line.

- Factory Setup Support: We assist international clients in establishing local radiator/condenser manufacturing plants, providing tailored solutions based on 15+ years of industry knowledge.

- Comprehensive Equipment Supply: We supply complete production lines (including CKD kits) and offer pre-sales & after-sales technical support. Our engineers provide on-site installation guidance.

- Full Component Supply: SUNHOPE is your single source for all essential radiator and condenser hardware and plastic components, guaranteeing supply chain reliability and finished product quality.

- Technical Expertise: As equipment users ourselves, we possess deep operational understanding, enabling us to quickly identify and resolve potential production issues.

- Extensive Mould Inventory: Over 200 proprietary head plate moulds covering most popular global vehicle models.

- Equipment Expertise: 10+ years of hands-on radiator manufacturing experience allows us to recommend and source optimal machinery for your needs.

- Superior After-Sales Support: Strong partnerships with equipment providers ensure prompt and effective service. Our user perspective enables faster, more accurate problem-solving.

- True One-Stop Solution: From factory design, equipment supply, and component sourcing to technical support - SUNHOPE delivers seamless integration for successful radiator production startup and operation.