-

Radiator Making Machine

-

Radiator Core Builder Machine

-

Radiator Fin Forming Machine

-

Ultrasonic Cleaning Machine

-

Industrial Vacuum Packaging Machine

-

Aluminum Brazing Furnace

-

Radiator Leak Tester

-

Radiator Tube

-

Plastic Radiator Tank

-

Aluminum Foil Sheets

-

Weldable Aluminum Sheet

-

Radiator Plate

-

Metal Working Lubricant

-

Aluminum Brazing Flux

-

Radiator Components

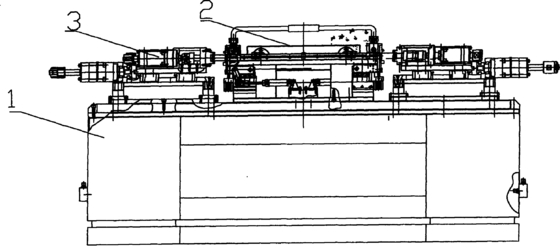

High Efficiency Radiator Core Builder Machine For 2 Rows Radiator Assambly Machine 220V

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Thickness Of Fin | Usually 8mm Or 5mm | Voltage, Power | 220V/50Hz,2.5kw |

|---|---|---|---|

| Manual Or Automatic | Pneumatics Or Servo Pneumatic | Fin & Tube Collocating Time | 1 Second Per Collocation |

| Conditions | New | ||

| High Light | High Efficiency Radiator Core Builder Machine,2 Rows Radiator Core Builder Machine |

||

Aluminum Radiator Core Builder Machine High Efficiency For 2 Rows Radiator Assambly Machine 220V

Product introduction:

Core assembly machine is the basic equipment for making radiator core and condenser core. This product is divided into manual core assembly machine, semi-automatic core assembly machine and full-automatic core assembly machine.

Manual core assembly machine: it is mainly used to assemble large cores with core size more than one meter and flat tube rows more than two rows.

Product applications:

It is used for assembling the aluminium core builder for 2 rows.

Product specifications:

| after-sale service | yes | mould | can customise |

| Air pressure requirements | 0.8Mpa | design style | can customise |

| Voltage, power | 220V/50Hz,2.5kw | Driving mode | Pneumatics |

| running speed | adjustable | Number of cylinders | 6--8 |

| production efficiency | 60sec. | Core size | 900*900*56mm |

| Number of preset models | Non. | Workstation | 1 |

| Programmable | Non. | Maximum size of head plate | 120mm |

![]()

![]()

About us:

With the development of heat exchange industry, more and more countries and regions are committed to building local radiator condenser plants. With our understanding of the industry, we have been helping foreign customers to set up radiator factories and provide the production machine in the region in the past five years. We provide customers with pre-sale and after-sale equipment design and service according to the size of our products.In the meantime we will also provide the material to our customers as well. We will send technicians to guide the installation on site to ensure the smooth production of the customer's factory, and provide free consultation service in case of any doubt in the production process.

If you are interested in setting up a radiator factory in your place or buying any products , please contact us and we will provide you with the best service and best price.

FAQ:

1.Does it can use different specifications of tubes in the same machine at the same time?

Yes ,it can install separately the size of 16,22,26,32mm and so on of different tubes.

2.Does it can assemble different heights of fins in the same machine ?

No,at the moment the core building machine only can assemble the cores which has single specification height of fins.If it needs to assemble different heights of fins,it needs to customize from us.